Packaging machinery relies on actuators to deliver precision and speed. Choosing the right actuator is crucial for efficiency. Electric actuators offer superior control compared to pneumatic ones. In this post, you'll learn why electric actuators are better for packaging machinery.

Actuators are devices that create motion by converting energy into mechanical movement. They serve as the "muscles" in machinery, enabling parts to move, rotate, or adjust positions. In industrial settings, actuators control valves, conveyor belts, robotic arms, and other equipment essential for automated processes.

Two main actuator types dominate packaging machinery: electric and pneumatic.

● Electric actuators use electrical energy to power motors that drive precise movements. These motors often turn screws or belts to move components smoothly and accurately. Electric actuators offer fine control over speed, position, and force.

● Pneumatic actuators rely on compressed air to push pistons inside cylinders. The air pressure creates linear or rotary motion. Pneumatic actuators are known for delivering high force quickly but often lack precise control.

Each type has its unique characteristics, benefits, and limitations, which influence their suitability for different packaging applications.

In packaging machinery, actuators perform critical tasks such as:

● Moving products along conveyor lines

● Opening and closing packaging flaps or lids

● Positioning items for labeling or filling

● Operating sealing or cutting tools

● Adjusting machine parts for different package sizes

Actuators must be reliable, fast, and accurate to maintain high production speeds and consistent package quality. The choice between electric and pneumatic actuators depends on the specific requirements of these tasks, including precision, speed, force, and operational costs.

When choosing actuators for packaging machinery, understanding their fundamental differences is crucial. Let’s explore how electric and pneumatic actuators vary in power sources, speed and control, and costs.

Electric actuators run on electricity, typically requiring a 24 VDC or higher power supply. They convert electrical energy into motion via motors that drive screws or belts. This direct power source means you only need wiring and a power supply to operate them.

Pneumatic actuators, on the other hand, rely on compressed air. They use air pressure to push pistons inside cylinders, creating motion. This setup demands an air compressor, air lines, valves, regulators, and fittings. The entire pneumatic system is more complex and requires regular maintenance to prevent leaks and ensure consistent air pressure.

Pneumatic actuators generally operate at a constant speed controlled manually or by simple valves. They provide quick, high-force movements but lack fine speed adjustments or precise positioning. Because air compresses, pneumatic actuators have limited accuracy and usually only support two-position operations — fully extended or retracted.

Electric actuators excel in speed control and precision. They use programmable controllers to adjust acceleration, deceleration, and position dynamically. This allows for smooth motion and exact stopping points, essential for delicate packaging tasks like labeling or filling. Electric actuators can achieve positional accuracy down to 0.0001 inches, far surpassing pneumatic options.

Pneumatic actuators often have a lower upfront cost for individual components. However, the total system cost includes the compressor, air lines, valves, and ongoing maintenance. Pneumatic systems tend to be less energy efficient; compressors can waste up to 85-90% of energy as heat, increasing operational expenses significantly.

Electric actuators have higher initial costs but offer lower energy consumption and reduced maintenance. They don’t require compressors or complex air systems, simplifying infrastructure. Over time, electric actuators can yield substantial savings in energy bills and maintenance downtime, improving total cost of ownership.

Tip: When evaluating actuators, consider total system costs — including energy, maintenance, and infrastructure — not just initial prices, to choose the most cost-effective solution for packaging machinery.

Electric actuators offer several key benefits that make them ideal for packaging machinery. Their precision, energy efficiency, and safety features stand out compared to pneumatic actuators.

Electric actuators provide exceptional control over motion. They can stop, start, and change speed smoothly. This fine control allows for highly accurate positioning, which is essential in packaging tasks like labeling, filling, or sealing. For example, electric actuators can achieve positional accuracy as tight as 0.0001 inches, ensuring consistent package quality and reducing waste.

Unlike pneumatic actuators, which often operate only in fully extended or retracted positions due to air compressibility, electric actuators can move to any point along their range. This flexibility supports complex packaging operations requiring variable positioning or delicate handling.

Electric actuators consume power only when moving. They don’t require a continuous energy supply to hold a position, unlike pneumatic systems that need constant compressed air. Pneumatic compressors often waste up to 85-90% of energy as heat, making them less efficient overall.

Because electric actuators use electricity directly, they convert energy more efficiently, lowering operational costs. Additionally, they require less maintenance since there are fewer moving parts and no air leaks to fix. Over time, these savings in energy and upkeep can offset the higher initial cost of electric actuators.

Electric actuators enhance safety in packaging machinery. They can stop immediately when power is cut, eliminating the risk of unexpected movement. Pneumatic actuators depend on trapped air pressure to hold position, which can leak and cause uncontrolled motion.

Electric actuators also have built-in protections against electrical shorts or overheating, shutting down automatically to prevent damage or accidents. This reliability is crucial during emergency stops, protecting both operators and equipment.

Tip: To maximize packaging line efficiency, choose electric actuators for tasks demanding precise control and energy savings, especially where safety and reliability are critical.

Pneumatic actuators have been popular in packaging machinery for many years. However, they come with several challenges that can impact efficiency, cost, and precision.

Pneumatic systems include many components beyond the actuator itself: compressors, air lines, valves, and regulators. These parts require regular maintenance to keep the system running smoothly. Air leaks are common and can be hard to locate, leading to wasted energy and increased downtime.

Valves and fittings wear out over time, causing failures that interrupt production. Repairing pneumatic systems often means replacing multiple components, which adds to labor costs and machine downtime. Additionally, pneumatic actuators need lubrication and can suffer from contamination if dust or moisture enters the system, increasing maintenance needs.

Compressed air generation is notoriously inefficient. According to the U.S. Department of Energy, compressors lose 85-90% of energy as waste heat. This inefficiency results in high electricity bills and a larger carbon footprint.

Moreover, pneumatic actuators require a continuous air supply to maintain position, consuming energy even when idle. The complexity of air delivery systems also causes pressure drops and leaks, further reducing system effectiveness.

In contrast, electric actuators consume power only during movement, offering significant energy savings over time.

Pneumatic actuators typically operate in simple two-position modes: fully extended or fully retracted. The compressibility of air makes it difficult to control speed or position precisely. This limitation affects packaging machinery tasks that require delicate handling, such as labeling or filling.

Because pneumatic actuators rely on mechanical stops to limit stroke length, repeated impacts cause wear and noise. This can reduce machine lifespan and increase maintenance frequency.

Electric actuators, however, provide smooth, programmable motion control with high positional accuracy, making them better suited for complex packaging operations.

Electric actuators shine in packaging machinery when precision movement is crucial. Their ability to stop exactly where needed makes them ideal for delicate tasks like labeling, filling, and sealing. For example, in a bottling line, electric actuators can position caps or labels with micrometer accuracy, reducing waste and improving product quality. Pneumatic actuators, by contrast, typically operate only in fully extended or retracted positions, limiting their usefulness in such precise applications.

Integration with advanced automation systems is another key advantage of electric actuators. They easily connect to programmable logic controllers (PLCs) and industrial networks, enabling real-time feedback and adaptive control. This capability supports complex packaging lines that require synchronization between multiple machines and sensors. Electric actuators can also communicate their position and status, allowing predictive maintenance and minimizing downtime.

Electric actuators perform best in environments with low moisture risk. Since they rely on electrical components, exposure to moisture can cause corrosion or short circuits if not properly sealed. Packaging lines handling dry goods, pharmaceuticals, or electronics benefit most from electric actuators. However, with proper sealing and enclosure, electric actuators can also be used in more humid settings.

In summary, electric actuators are the top choice when you need:

● Precise, repeatable motion for delicate packaging tasks

● Seamless integration with digital control and automation systems

● Operation in environments with controlled moisture levels

These scenarios highlight where electric actuators deliver superior performance, reliability, and efficiency compared to pneumatic options.

When deciding between electric and pneumatic actuators for packaging machinery, looking beyond initial costs is key. Total cost of ownership (TCO) includes purchase price, installation, maintenance, energy use, and labor impact. Let’s break down these factors.

Pneumatic actuators usually cost less upfront. The cylinders themselves are simple and inexpensive. However, pneumatic systems require extra equipment — compressors, air lines, valves, and regulators — which add to installation costs and complexity. Maintenance costs can also be high due to leaks, worn valves, and compressor upkeep.

Electric actuators come with a higher initial price tag. They need motors, controllers, and wiring. But they don’t require compressors or complex air delivery systems. This reduces infrastructure expenses and lowers maintenance needs. Over time, electric actuators save money through reduced energy consumption and fewer repairs. Many users find that these savings offset the higher upfront investment within a few years.

Electric actuators need a reliable power source and communication lines for control signals. Wiring is simpler than pneumatic air lines and less prone to leaks or damage. Installation can be faster and cleaner since no air compressors or piping are needed.

Electric systems also integrate easily with automation and control platforms. This reduces setup time and allows for future upgrades or expansion. Packaging plants with existing electrical infrastructure can adopt electric actuators without major modifications.

In contrast, pneumatic systems require a dedicated compressed air network. Compressors consume significant energy and require space and ventilation. Air lines and fittings add complexity and potential leak points. Maintaining these systems demands skilled technicians and regular inspections.

Electric actuators create quieter, cleaner working environments. Without noisy compressors or hissing air leaks, operators experience less fatigue and distraction. This can improve focus and reduce errors on packaging lines.

Maintenance teams benefit too. Electric actuators have fewer moving parts and no air leaks to diagnose. Troubleshooting is often simpler, requiring less downtime. Younger technicians often prefer working on electric systems due to their familiarity with electronics and programming.

Reduced noise and cleaner conditions can boost worker morale and retention. In industries facing labor shortages, this advantage is significant. Happier workers tend to be more productive and contribute to smoother operations.

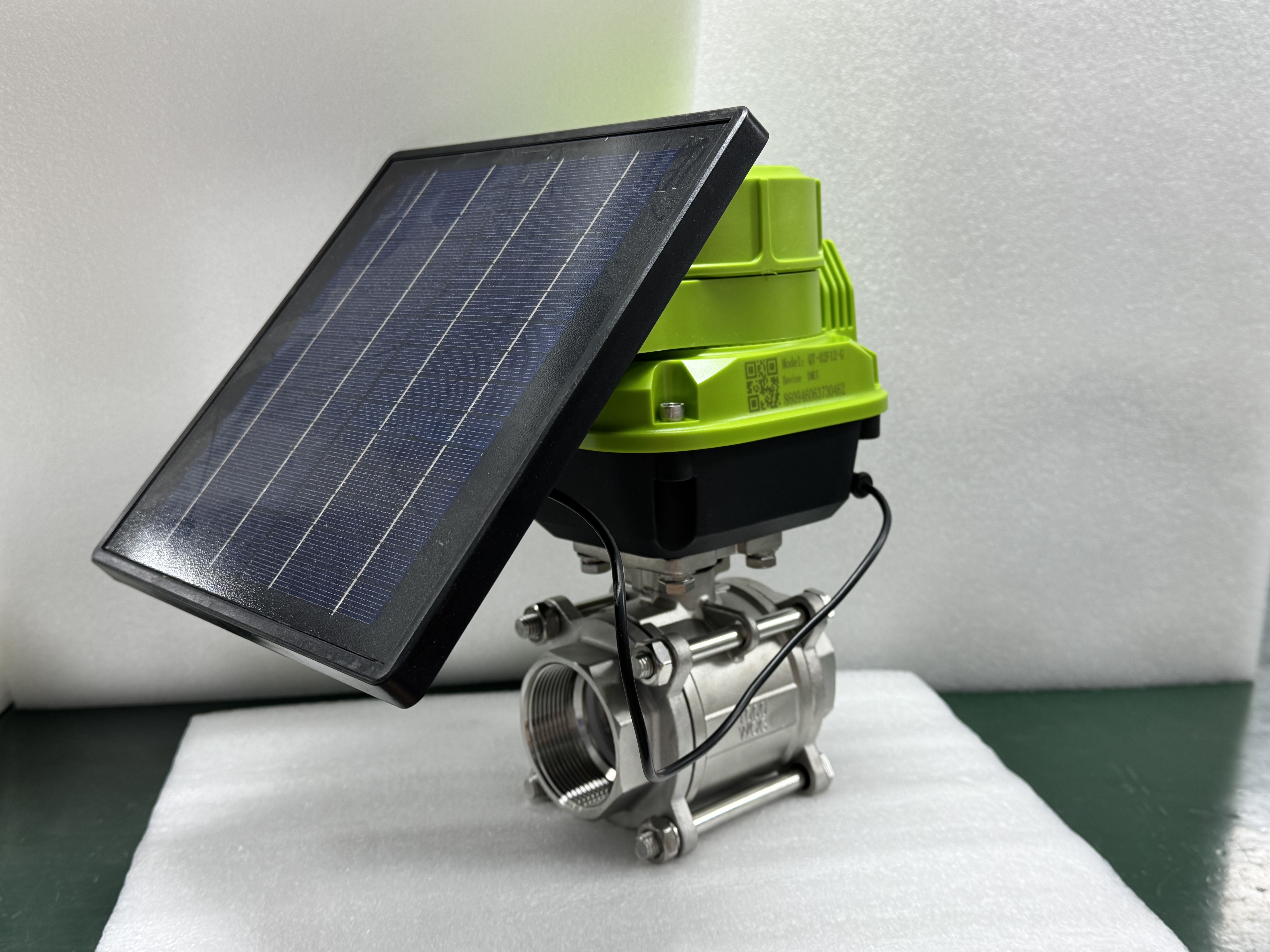

Electric actuators offer superior precision, energy efficiency, and safety for packaging machinery, outperforming pneumatic counterparts. When selecting actuators, consider total system costs, including energy and maintenance. Future trends in actuator technology emphasize integration with smart systems and improved sustainability. Shenzhen Power-Tomorrow Actuator Valve Co., Ltd. provides innovative actuator solutions, enhancing performance and reliability. Their products deliver value through advanced features and seamless integration, meeting the evolving needs of modern packaging operations.

A: An Electric Actuator is a device that uses electrical energy to power motors, enabling precise movements in machinery, crucial for tasks like labeling and filling in packaging processes.

A: Electric Actuators enhance efficiency by offering precise control over motion, reducing energy consumption, and minimizing maintenance needs, leading to consistent package quality and lower operational costs.

A: Electric Actuators provide superior precision, energy efficiency, and safety features, making them ideal for packaging machinery compared to Pneumatic Actuators, which lack fine control and require more maintenance.

A: Electric Actuators have higher initial costs but offer long-term savings through reduced energy use and maintenance, offsetting the upfront investment compared to Pneumatic Actuators.

A: Electric Actuators easily connect to programmable logic controllers (PLCs) and industrial networks, enabling real-time feedback and adaptive control for advanced packaging line automation.